Manufacturers offer a choice – how do you decide which is best for you?

Copper vs Aluminum Busway | By Data Center Dynamics

Contents

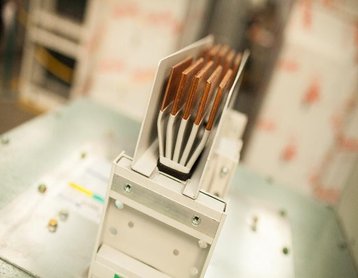

Copper and aluminum are the two most common conductors used in electrical equipment, including busway trunking systems.

Copper is one of the oldest known metals, recognized today for its strong ductility, tensile-strength, thermal-conductivity, and thermal-expansion properties. Traditionally, copper was the conductor of choice for busway trunking systems. However, in more recent years the use of aluminum conductors has become more prevalent in the global busway trunking market, offering certain advantages that copper cannot compete with. As a result, many busway manufacturers now offer both copper and aluminum solutions, affording engineers more choice. Therefore, it is important for engineers to understand the true benefits and drawbacks of each material as a conductor in busway trunking applications to facilitate smart decision making.

Conductivity

@Datacenterdynamics,

www.datacenterdynamics.com

Aluminum has 62 percent the conductivity of copper, which often leads specifying engineers to disregard aluminum as a viable conductor for busway trunking systems. The lower conductivity of aluminum means that a much larger size of conductor will be required to match current carrying capacity of a copper conductor.

However, aluminum can be as much as 70 percent lighter than copper. Even when taking the larger size of an aluminum system, the busway will still weigh significantly less than a copper system of equal conductance. The reduced weight of aluminum conductors can create cost savings in many areas, with fewer supports required to secure the busway, less manpower required for installation and reduced transportation costs. Similarly, when you compare conductivity by weight, you will find that aluminum is actually 50 percent more conductive per kg.

Granted, the larger overall dimensions of an aluminum busway system may be restrictive in certain applications such as small buildings or underfloor applications. However, if size is not an obstacle for your specification, but weight restrictions do apply, aluminum may be the best choice to maximize conductivity whilst minimizing cost.

Ratings

When compared by volume, copper outperforms aluminum when it comes to electrical ratings. Boasting a lower electrical resistance, lower power loss, lower voltage drop and higher ampacity. All of which contribute to the electrical efficiency of the busway trunking system.

However, when compared by weight, aluminum is more electrically efficient. Again, this can be attributed to aluminum having a density 70 percent lower than copper, making it the perfect choice where busway sizing is a non-issue.

Busway Trunking System

At LKHPD, our busway (a.k.a Busbar trunking system, bus duct) is the first of its kind to be designed and tested with full testing facilities in Singapore. Reliable, flexible & customizable, simple and efficient are some of the main features of our busway.

Price

The price of copper is much more volatile than aluminum, heavily influenced by consumer demand amongst other political and economic factors. According the London Metal Exchange, the price ratio of copper to aluminum is currently over 3:1, representing a significant cost difference.

As a result, aluminum allows specifiers and contractors to compile cost forecasts with more accuracy and has consistently provided huge project cost savings passed on from the busway manufacturers. This presents a huge advantage in today’s highly competitive power distribution market where cost has become a key concern for all parties involved.

Environmental sustainability

Whilst both aluminum and copper are 100 percent recyclable, differences in how each metal is recycled and mined/extracted impact their environmental sustainability.

When considered on a percentage basis, aluminum is the most recycled industrial metal with 75 percent of aluminum ever produced still in use today. Comparing this to the 65 percent of copper that is still in use or available for use. Similarly, the recycling process for aluminum uses only 5 percent of the energy required for primary production and releases only 5 percent of the associated emissions. Again, although copper can also be recycled at a reduced environmental cost, the process is different, using a 15 percent of the energy required to mine and extract the same copper. With this in mind, aluminum is arguably a more sustainable option for busway trunking conductors as it is less reliant on non-eco mining and extraction processes and can its recycling processes produce less energy waste.

Conclusion

Although the debate on which metal is the most suitable is subjective to individual specifications and project limitations, we hope to have shed some light on the benefits and drawbacks of both copper and aluminum busway trunking conductors that will aid your future decision making.

David Bradley, E+I Engineering

David Bradley is technical sales manager (London) at E+I Engineering.

Source: https://www.datacenterdynamics.com/en/opinions/busbars-copper-versus-aluminum/