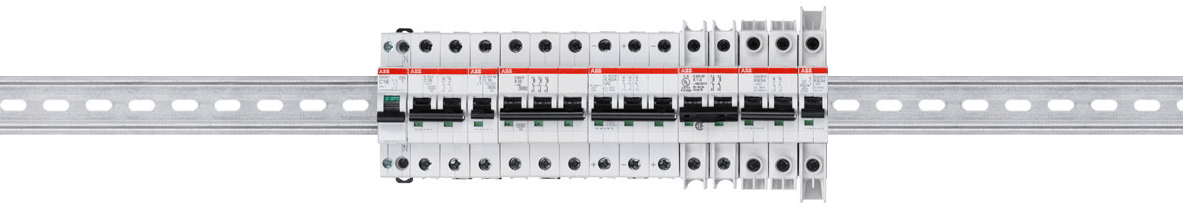

Miniature circuit breakers (MCBs) ensure electrical safety in homes, offices, and other buildings as well as for industrial applications by protecting electrical installations against overloads and short circuits. Once a fault is detected, the miniature circuit breaker automatically switches off the electrical circuit to prevent damage to wires and to avoid the risk of fire. Warranting reliability and safety for people and assets, MCBs are equipped with two tripping mechanisms: the delayed thermal tripping mechanism for overload protection and the magnetic tripping mechanism for short circuit protection.

MCB | How does a miniature circuit breaker actually work?

Contents

What is a MCB?

MCB Working Principle

Just imagine you live in an apartment built maybe sometime in the 60s. You’ve just decided to get your annual spring clean over and done within record time tonight. In preparation, you’ve compiled your favorite MP3 playlist on your PC and it’s being streamed in all rooms. You’ve filled the dishwasher and turned it on, the washing machine is full of clothes and you’ve flicked the switch, you’ve pulled the vacuum cleaner out of its corner and plugged it in.

Not long after, you hear a quiet ‘CLICK’ from the corner (or, in the case of older apartments, from out in the hallway). The lights are out, the music is only playing in a couple of rooms or not at all, the washing machine and the dishwasher are off and the vacuum cleaner has fallen silent.

You’re annoyed, and you try to figure out what’s going on. Usually, ‘the cause’ can be located quite quickly: that ‘thing’ in the box on the wall is off. So, you switch it back on, and off you go. Moments later, the circuit breaker once again clicks to cut off the overload. In a pinch, you might even get the bright idea that you might be able to jam the switch in the ON position so that you can just finish vacuuming your apartment.

What happened?

Annoyingly, doing that won’t let you effectively clean your apartment nowadays. Our ABB miniature circuit breaker will, thankfully, protect your wires from both overloads and short-circuits even if the switch has been forced into the ON position, due to what we call a ‘trip-free’ MCB. Even if your finger keeps the switch in the on position, the internal mechanism will trip and ensure safe disconnection of the overloaded circuit.

What exactly does an MCB do?

The short answer: it protects wires from overloads and short-circuits. When we look on the inside of an MCB we can see how that actually works.

For overload protection the temperature of a bimetal, through which the current passes (yellow area), is decisive. If the nominal current—the current the circuit breaker is designed for—rises slightly, the bimetal heats up to a greater extent and, after a certain period of time, this causes the switching mechanism to trip.

Short-circuit protection is located in the electromagnetic coil (green area). In the event of a short-circuit, the current rises very sharply and the coil creates a magnetic field that both trips the switching mechanism and opens the contacts via a quick-release mechanism. The additional quick release for opening the contacts in the event of a short-circuit helps to keep the energy of the short-circuit to a minimum, which in turn keeps the ‘stress’ the wires are subjected to, as low as possible.

In both cases, i.e. short circuit or overload, the shutdown process results in an electric arc between the contacts of the MCB. This electric arc is actually counterproductive when trying to ensure a separation of the two circuits. In order to extinguish the arc, which has a temperature of more than several thousand degrees Celsius, it must be directed away from the contacts, over the arc runners, and past the prechamber plates to the arc chamber (blue area). In the arc chamber, the formerly powerful electric arc is split into several smaller arcs until the driving voltage is no longer sufficient and they are extinguished.

Today MCBs are installed in all our homes, offices, and other buildings, protecting the electrical wires from damage. The fundamental principle, however, is based on the first “electromagnetic circuit breaker” patented by Hugo Stotz in 1924. Since then MCBs have been further advanced, continuing the pioneering spirit of Hugo Stotz. These MCBs are produced nowadays at our Heidelberg site in a cutting-edge manufacturing plant, which has recently been awarded the Industry 4.0 award.

For overload protection the temperature of a bimetal, through which the current passes (yellow area), is decisive. If the nominal current—the current the circuit breaker is designed for—rises slightly, the bimetal heats up to a greater extent and, after a certain period of time, this causes the switching mechanism to trip.

Short-circuit protection is located in the electromagnetic coil (green area). In the event of a short-circuit, the current rises very sharply and the coil creates a magnetic field that both trips the switching mechanism and opens the contacts via a quick-release mechanism. The additional quick release for opening the contacts in the event of a short-circuit helps to keep the energy of the short-circuit to a minimum, which in turn keeps the ‘stress’ the wires are subjected to, as low as possible.

In both cases, i.e. short circuit or overload, the shutdown process results in an electric arc between the contacts of the MCB. This electric arc is actually counterproductive when trying to ensure a separation of the two circuits. In order to extinguish the arc, which has a temperature of more than several thousand degrees Celsius, it must be directed away from the contacts, over the arc runners, and past the prechamber plates to the arc chamber (blue area). In the arc chamber, the formerly powerful electric arc is split into several smaller arcs until the driving voltage is no longer sufficient and they are extinguished.

Today MCBs are installed in all our homes, offices, and other buildings, protecting the electrical wires from damage. The fundamental principle, however, is based on the first “electromagnetic circuit breaker” patented by Hugo Stotz in 1924. Since then MCBs have been further advanced, continuing the pioneering spirit of Hugo Stotz. These MCBs are produced nowadays at our Heidelberg site in a cutting-edge manufacturing plant, which has recently been awarded the Industry 4.0 award.